|

|

| Mobile-sized | ||

| This site: | ||

| Home | ||

| Copyright | ||

| Let the Devil Wear Black: | ||

| Briefly. | ||

| ||

| Additional Resources... | ||

| James Linden: | ||

| Background | ||

| Contact | ||

Resources - Siphon breaks

What are they, how do they work and what happens if they are not there?

Chapter 2

The idea behind a dip–pipe is that you can unload a pressurised tank from a pipe that leads out of the top of the vessel. This has an advantage that it can reduce the number of places in a pressure vessel that has a hole cut through it and also it means that if you have very limited access to the lower half of a tank, you can do everything from the top.

Pressure vessels are expensive and many are re–used — that is how you can end up with a pressure vessel that has a dip–pipe in a situation where you should not have one, like the Ethylene Oxide and Propylene Oxide tanks padded to 3 Bar pressure with nitrogen, on the plant in the book.

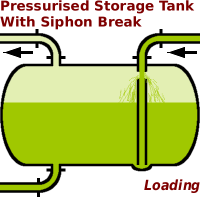

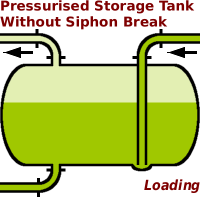

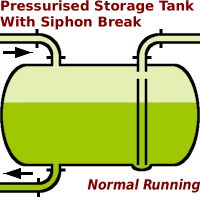

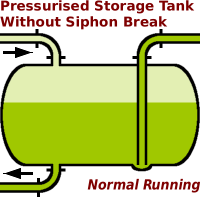

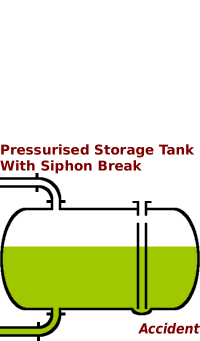

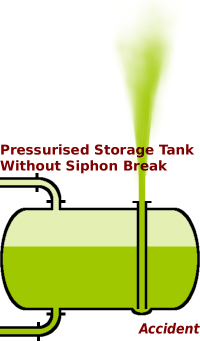

Comparison of how tanks with and without a siphon break modification on pre-existing dip-pipes work under various conditions. Dip–pipe modified with siphon–break Dip–pipe not modified

The disadvantage of top–loading liquid into a partially pressurised tank is that some of the padding gas (in this case nitrogen) dissolves in it — this will happen whether you are looking at a dip–pipe tank with a siphon–break or with a normal loading pipe that goes into the top of the tank.

In the case of the dip–pipe with the siphon–break, you can get padding gas being entrained with the liquid being loaded as virtually all of it flows down the dip–pipe to the bottom of the vessel, or, you can get liquid hitting the side of the siphon–break holes and spraying out into the vessel, picking up padding gas on the way — depending on: flow–rates; viscosity; pipe diameter; levels; the shape of the delivery pipework just before it enters the vessel; and, so on.

The surface is not broken thus there is no opportunity for the padding gas to dissolve into the liquid that is being loaded, other than would normally take place once loading had finished, with the obvious exception of the fact that the concentration of padding gas in the liquid will be lowered as the liquid moves around as the tank is filled.

With loading, one important disadvantage is that should the loading line fail, the tank can empty out again, through the loading line, all over the lorry or wherever the failure is. Simple one–way valves are all that are needed to cure this but remember that trusting a one–way valve is more of an act of faith than anything else and you should have another plan as they fail notoriously easily.

Everything is just hunky–dory.

As far as the plant is concerned, it all runs all right.

The disadvantage as far as safety is concerned is that you have pressurised liquid going towards the tanker unloading bay (obviously, you have a valve somewhere) all of the time that the plant is running and there is no unloading happening — the unloading bay, therefore, is not manned thus, if anything goes wrong, it is less likely to be noticed at the time.

A further consequence of that is that you can end up with between–valve lengths of pipe that have only liquid in them therefore any S.O.P. should include blowing–out the pipes after unloading. However, that is yet another source of fugitive emissions.

Pressurised gas escapes to atmosphere, leaving the liquid in the tank.

Once the pressure has equalised, the only escapes from the tank will be as a result of dissolved padding gas coming out of solution and taking vaporised liquid or droplets of liquid with it, as it escapes through the siphon–breaks and out through the broken pipe.

Another way that gas and vapour/liquid droplets can escape is that when the tank depressurised, the gas inside cooled down adiabatically and therefore is quite cold. As it heats up, it will expand, pushing out the vapour/droplets with it.

It probably pays to be aware that there will still be vapour leaking from the tank once it has depressurised and that it will probably be flammable as well — if a flame gets inside the tank, you can end up with an explosion if the flammable chemical has no upper explosive limit, such as Ethylene Oxide.

Despite having the inlet pipe knocked off completely, the tank remains completely pressurised and will remain so unless steps are taken to do something about it such as vent it through another pipe.

At 3 bar (gauge), a tank that is slightly over two thirds full (almost three quarters, depending upon how far above the piping failure is from the surface of the liquid in the tank) will empty completely through the dip–pipe if no steps are taken to reduce the gas pressure in the tank.

Siphon–breaks on dip–pipes therefore are a must. Having them on the plant flowsheets but not on the actual plant is fraud.

“That’s if they don’t already know. Somebody’s bankrolling all of this. They think it’s money well spent,” he said.