|

|

| Mobile-sized | ||

| This site: | ||

| Home | ||

| Copyright | ||

| Let the Devil Wear Black: | ||

| Briefly. | ||

| ||

| Additional Resources... | ||

| James Linden: | ||

| Background | ||

| Contact | ||

Resources - Butt/lap joints

Differences in the stresses involved - comparing the two in this case.

Chapter 3

The flat roof between the two production buildings on either side had a number of rolled steel joists — RSJs — protruding through the waterproof surface, to a height of around two feet or so.

They were all the same height and were arranged in a square array, between one and two metres apart, as though there had been something on that roof — such as storage tanks or some processing equipment — or whoever constructed the building had a tremendous amount of foresight.

The drier vent tower had to be bolted to the roof, using the existing RSJ stubs and we all knew from other examples that were dotted around the plant, how this should be done.

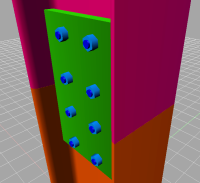

You can see in the image how the magenta RSJ — from the tower — butts up to the end of the orange RSJ — the stub on the flat roof. All of the weight of the tower is on the ends of the RSJs as a compressive force.

The green plates are there simply to stop the ends of the RSJs from sliding off each other if a sideways force should be applied — such as in a strong gust of wind.

The blue bolts just hold the plates in place and unless there is a sideways force, they don’t have that much force on them.

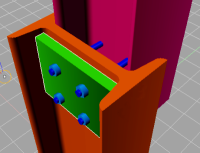

It came as something of a shock to all of us to discover that instead of using the ends of the RSJs end–to–end as above, ‘Gurj’ had decided instead to design the vent tower so that the gap in between the legs was smaller than the space between the RSJ stubs so that he could lap them.

In this configuration, the RSJs are free to slide over each other because the contacting surfaces are parallel to the direction of force. This means that the only things that are stopping them from sliding past each other are the bolts.

You can see here that the bolts just hold the plates in place which it turn, stop the RSJ ends from sliding around — you could take out all but one bolt from each RSJ without any nett effect.

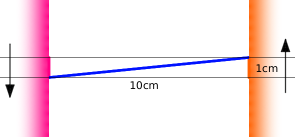

Here, you can see how the two RSJs sliding over each other makes the bolts bend downwards and take on a force that bolts are not designed to take — a sheer force.

The bolts are no longer at right–angles to the plates and are being stretched and bent with a horrendous amount of force.

The amount of vertical displacement that the bolts had on them was around 1cm over a length of 10cm. So, for each tonne of vertical force, the bolts have a tension between them of roughly ten tonnes.

With four bolts on four legs, a four tonne tower will put a strain of two and a half tonnes on each bolt as well as a sheer force.

That is why this is such a spectacularly bad way of joining a tower to the RSJs on the flat roof. That is why the tower gained the name ‘Kanvinde Towers’ and everybody joined in with the running joke.

A company’s most valuable employees are the ones that don’t work for it any more.