|

Let the Devil Wear Black | James F Linden. The true story of the Courtaulds Cancer-Gas Scandal. |

Resources - Degassing feedstock

Changing the plant without much thought.

Chapter 20

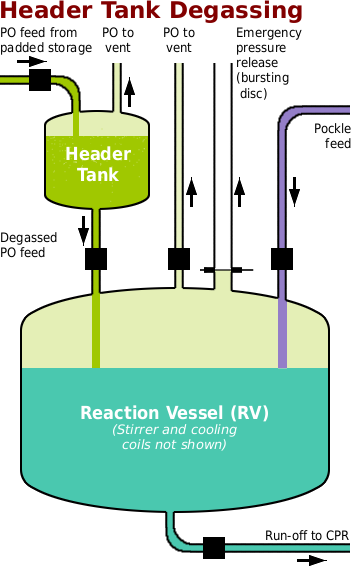

The original design for the 245 and 328 plants had a header tank between the padded EO and PO storage tanks and the reactors.

EO and PO were fed into their respective header tanks whereupon, the nitrogen would ‘fizz’ away, each escaping through a vent that was protected by a flame trap.

The EO was then vaporised — it only boils at around 11C any way — and fed into the reactor as a gas which was then absorbed through the surface of the liquid in the RV as it splashes around whilst it is stirred. The PO was fed in directly as a liquid.

Then, somebody had the idea of taking the header tanks out and having the feeds from the storage tanks fed directly into the vaporiser or RV — for EO and PO respectively.

The problem with doing that was that the dissolved nitrogen padding from the storage was still in the feed to the reactor where it built up in the header space above the liquid. It just built up and didn’t have anywhere to go. As a result, they now had to vent it at regular intervals and if anything, increasing the amount of EO and PO released into the environment.

The reason for the increased level of emissions over those of using a header tank that is vented is simply that the reactors run at around 70C whereas the EO and PO from the storage tank is at less than 20C. The increase in temperature means a higher vapour pressure, thus a higher concentration of EO and PO in the vents.

This venting had to be done several times a day; the gas had a higher concentration of EO and PO than using the header tanks; and, the gradual increase in pressure in the reactor, followed by a sudden loss of pressure during venting meant that the reaction was not as predictable — especially in the case of the reactor that used EO.

That changed things, we might not know when the company was going to have a disciplinary hearing but we already knew the result.

Copyright © 1994-2023 James F Linden. All Rights Reserved.